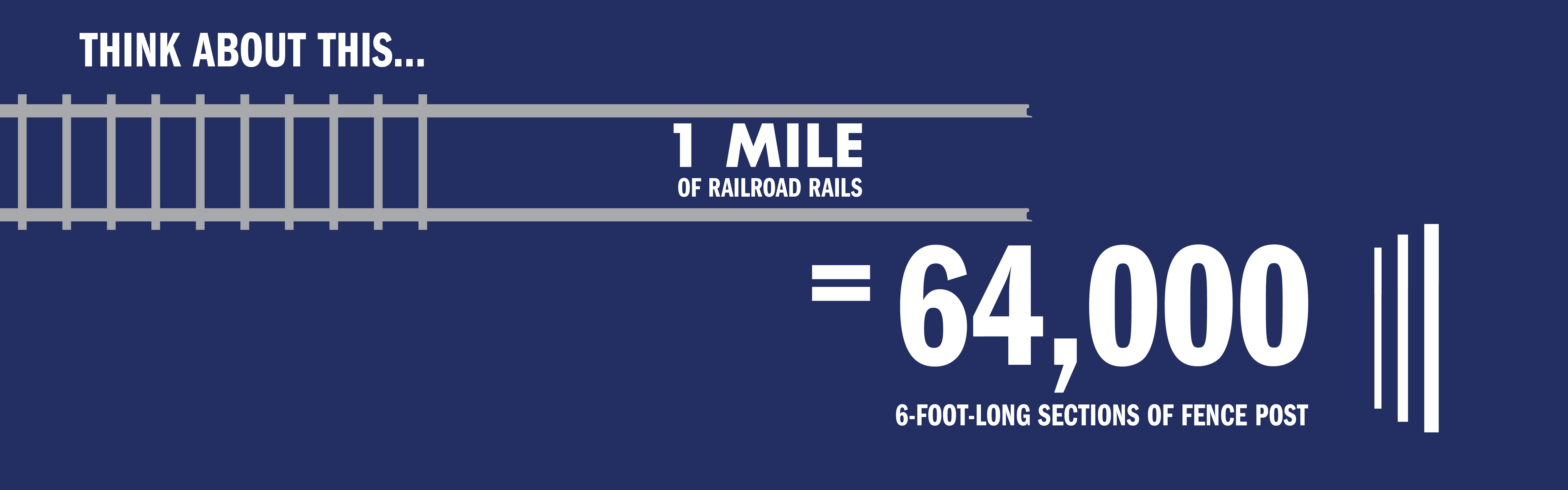

That works out to 73 miles of fence post - which would be 1,075 football fields laid end to end! Talk about the ultimate in recycling - a product that has been around for generations being re-formed into a product that will be used for generations to come!

OUR PROCESS

The quality realized in rail-steel products can be attributed to the quality initially manufactured into all railroad rails. There simply is no other high carbon steel product which is produced and controlled as carefully as these rails.

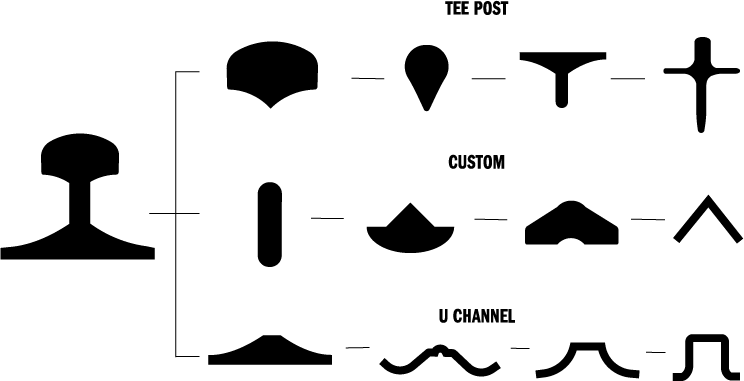

When rails are taken out of service, Chicago Heights Steel makes sure they meet strict inspection standards for high quality before being purchased for rolling. During production, the rails are slit into three parts: head, web and flange. Each part is then rolled to a predetermined shape and size by a series of rolls. A section of rail steel can be transformed into tee posts, U-channel posts, or custom products in a mere four hours. Check out the process below.

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

CHS purchases the majority of its rail steel from North America and Canada. Sections of the rail steel are loaded onto the conveyer. Any residual oil is burned off the sections of rail steel prior to moving into the furnace.

CHS purchases the majority of its rail steel from North America and Canada. Sections of the rail steel are loaded onto the conveyer. Any residual oil is burned off the sections of rail steel prior to moving into the furnace.

The rail steel is moved into the furnace, where it will be heated to 2200 degrees – a process which takes 40 minutes. The skilled CHS team processes 1200 pieces of rail steel in one 8-hour shift.

The rail steel is moved into the furnace, where it will be heated to 2200 degrees – a process which takes 40 minutes. The skilled CHS team processes 1200 pieces of rail steel in one 8-hour shift.

Once the glowing red steel is ready and the signal is given, the operator pushes the individual rail out of the furnace, using a water-cooled machine.

The 2200 degree section of rail steel moves down a series of rollers where it will be split into three separate parts: head, web and flange.

The 2200 degree section of rail steel moves down a series of rollers where it will be split into three separate parts: head, web and flange.

Each part is then rolled to a predetermined shape and size by a series of rollers.

Each part is then rolled to a predetermined shape and size by a series of rollers.

Once the U-channel or tee posts are formed, the 150-foot-long sections are sent to the cutter, where they will be cut into their finished length. After cutting, they are sent to be painted.

Once the U-channel or tee posts are formed, the 150-foot-long sections are sent to the cutter, where they will be cut into their finished length. After cutting, they are sent to be painted.

Studded tee posts are lined up to be given finish coat of industrial quality paint.

Studded tee posts are lined up to be given finish coat of industrial quality paint.

The weather resistant painted tee posts are sent through dryers to set the paint in just a short amount of time.

The weather resistant painted tee posts are sent through dryers to set the paint in just a short amount of time.

Posts are given a secondary coat of paint in the signature CHS colors. In an 8-hour shift, 48,000 posts can be painted on the two painting lines!

Posts are given a secondary coat of paint in the signature CHS colors. In an 8-hour shift, 48,000 posts can be painted on the two painting lines!

The finished tee posts are tagged, bundled and brought to the warehouse for future shipment to customers.

The finished tee posts are tagged, bundled and brought to the warehouse for future shipment to customers.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

It’s the ultimate in recycling, reusing and repurposing! Steel has the durability needed to last for centuries. Take a look at how Chicago Heights Steel, the largest rail recycler in the United States, makes what’s old new again.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

From decades-old rail steel to steel fence posts in a mere four hours! Chicago Heights Steel’s skilled and dedicated team of employees process a product that has been used for numerous years, as an integral part of a railway system, into tee posts and signposts that will be used for countless years into the future.

CHS purchases the majority of its rail steel from North America and Canada. Sections of the rail steel are loaded onto the conveyer. Any residual oil is burned off the sections of rail steel prior to moving into the furnace.

CHS purchases the majority of its rail steel from North America and Canada. Sections of the rail steel are loaded onto the conveyer. Any residual oil is burned off the sections of rail steel prior to moving into the furnace.

The rail steel is moved into the furnace, where it will be heated to 2200 degrees – a process which takes 40 minutes. The skilled CHS team processes 1200 pieces of rail steel in one 8-hour shift.

The rail steel is moved into the furnace, where it will be heated to 2200 degrees – a process which takes 40 minutes. The skilled CHS team processes 1200 pieces of rail steel in one 8-hour shift.

Once the glowing red steel is ready and the signal is given, the operator pushes the individual rail out of the furnace, using a water-cooled machine.

The 2200 degree section of rail steel moves down a series of rollers where it will be split into three separate parts: head, web and flange.

The 2200 degree section of rail steel moves down a series of rollers where it will be split into three separate parts: head, web and flange.

Each part is then rolled to a predetermined shape and size by a series of rollers.

Each part is then rolled to a predetermined shape and size by a series of rollers.

Once the U-channel or tee posts are formed, the 150-foot-long sections are sent to the cutter, where they will be cut into their finished length. After cutting, they are sent to be painted.

Once the U-channel or tee posts are formed, the 150-foot-long sections are sent to the cutter, where they will be cut into their finished length. After cutting, they are sent to be painted.

Studded tee posts are lined up to be given finish coat of industrial quality paint.

Studded tee posts are lined up to be given finish coat of industrial quality paint.

The weather resistant painted tee posts are sent through dryers to set the paint in just a short amount of time.

The weather resistant painted tee posts are sent through dryers to set the paint in just a short amount of time.

Posts are given a secondary coat of paint in the signature CHS colors. In an 8-hour shift, 48,000 posts can be painted on the two painting lines!

Posts are given a secondary coat of paint in the signature CHS colors. In an 8-hour shift, 48,000 posts can be painted on the two painting lines!

The finished tee posts are tagged, bundled and brought to the warehouse for future shipment to customers.

The finished tee posts are tagged, bundled and brought to the warehouse for future shipment to customers.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Strong and resilient… rail steel products deliver one of the best values in the industry today.

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

Chicago Heights Steel products are 100% American made and 100% recycled. With more than 100 years of experience, CHS is the steel specialist. Our steel is tested and inspected to meet strict requirements and our steel products are manufactured quickly and economically. See what Chicago Heights Steel can do for you!

211 E. Main Street Chicago Heights, IL 60411

© Chicago Heights Steel

Phone Number: 1 (708) 756-5648 | Toll Free: 1 (800) 424-4487 | Fax Number: 1 (708) 756-5628

Phone Number: 1 (708) 756-5648

Toll Free: 1 (800) 424-4487

Fax Number: 1 (708) 756-5628

211 E. Main Street Chicago Heights, IL 60411

© Chicago Heights Steel